As the Quantum Colaboratory (Quantum Colab) continues to grow and strengthen as a resource for Canadian researchers, users can benefit from increased cross-node engagement. Visitations between staff have aimed to enhance the understanding of each node’s expertise and the available tools and processes in each node and the ease of transfer between nodes to improve the user experience. For example, rather than having to travel to each node, users may benefit from Quantum Colab capabilities that enable fabrication or characterization work for individuals to be performed at other Quantum Colab nodes and dynamic workflows and processes that are synchronized across nodes and present best practice.

CVD growth capabilities at the Quantum Nanofabrication and Characterization Facility (QNFCF) at the University of Waterloo (UW) are regularly utilized by the University of British Columbia (UBC) researchers. Recently, QNFCF staff assisted Dr. Kaigala’s team in the Life Science Institute at UBC in fabricating photoconductive devices with hydrogenated amorphous silicon, a-Si:H. Deposition tests with different parameters were done in the Oxford PECVD system in the QNFCF cleanroom, while the photoconductivity measurements were conducted at UBC. The QNFCF cleanroom also enabled anodic bonding for microfluidic application to be completed in the new SÜSS wafer bonder. Professional staff across nodes continue to explore improved methods of accessing new fabrication or characterization techniques and the use of the QNFCF’s Oxford DRIE system to fabricate the microfluidic channels.

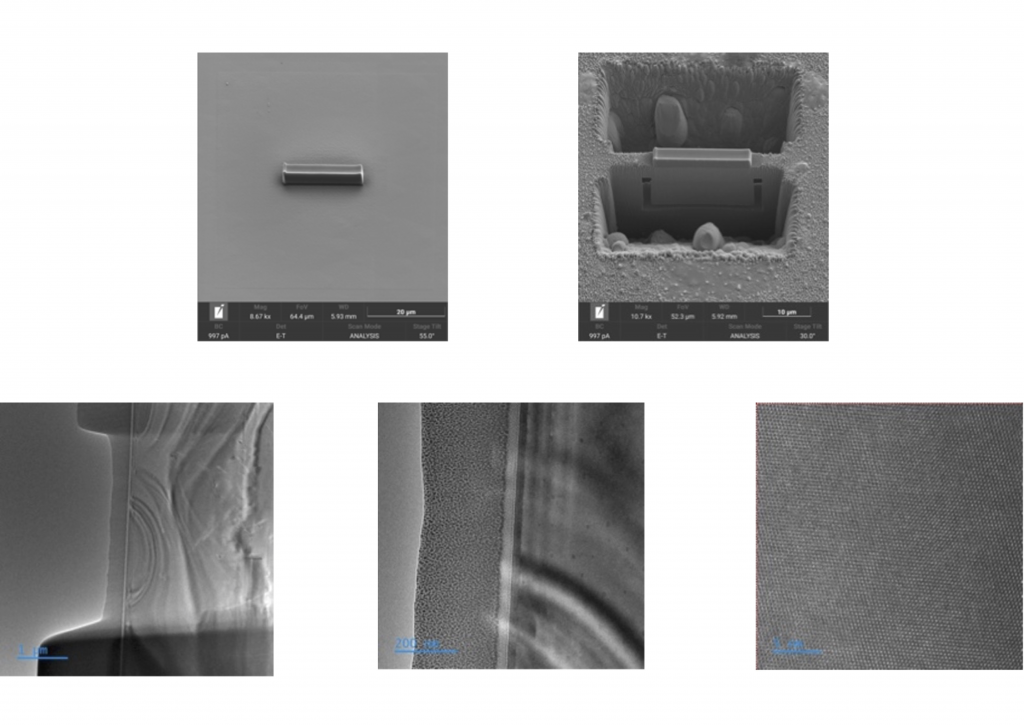

Joint workflows and processes are also impacting Focused Ion Beam (FIB) tool capabilities. Most Transmission Electron Microscopy (TEM) sample preparation for semiconductors and thin films requires using a FIB. UBC’s Miles Brodie, a student and staff researcher, is an expert in FIB with over 15 years of experience. While Waterloo has a focused ion beam (FIB), it has less experience applying this technology to TEM sample preparation. “At QNFCF, we are limited in experience regarding TEM sample preparation using FIB. UBC can help us by sharing their expertise as we work through samples together,” says Nathan Nelson-Fitzpatrick, Director of the QNFCF, adding that “in reciprocity, the QNFCF is bringing on-line a newly installed JEOL F200 TEM, which can benefit the community at UBC by providing them with high-quality electron micrographs and other cutting edge analyses.”

In evidence of this partnership, III-V multilayer and quantum well samples from Zbig Wasilewski’s group were prepared for TEM imaging using the FIB at UBC. Miles Brodie also shared qualitative observations and FIB process information, enabling the Waterloo team to improve the FIB sample workflow on their own ZEISS FIB system. “We are using this as a learning opportunity. By sharing process flow and comparing results across nodes, Waterloo gains improved FIB internal pipelines and processes. Strengthening the FIB operations across both nodes also safeguards against site failure; if one node’s FIB ever goes down, samples can be processed at the other node instead,” says Nelson-Fitzpatrick.

This collaboration is expected to open a pathway for sample and analysis exchange between the two nodes and facilitate knowledge transfer between sites. It presents a unique opportunity to develop a shared FIB TEM workflow for the benefit of all Quantum Colab users.